The boss came through for me, so I cooked up a placard as a thank you that features the Bureau’s three goals, surrounded by the six core values. It’s about the size of a phonograph record.

All posts by Swissninja

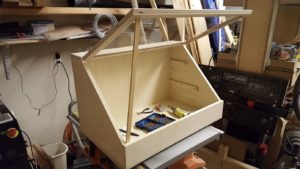

Retirement Craft Box

Museum-Style Display Case

A few months ago, Schenk’s wife Lisa asked me if I could make a new display case for some of the fancier geological specimens she’s found throughout the years. The style would be the slant-top kind found in museums or historical societies. Yeah, I can do that.

A few months ago, Schenk’s wife Lisa asked me if I could make a new display case for some of the fancier geological specimens she’s found throughout the years. The style would be the slant-top kind found in museums or historical societies. Yeah, I can do that.

Box is made with birch ply I had leftover from another project. The ‘glass’ is actually a sheet of plexiglass, which is a lot lighter (and easier to work with; god I hate working with glass).

Like most wood projects, it looked pretty ‘meh’ when it was done, but Lisa applied some stain, and when stocked with geological and biological treasures, it came out lookin’ pretty damn good.

More Nurse Glasses

After the popularity of the first set of glasses I gave away, I trolled the internet for more funny ideas. I found a few more, drafted them up, then went to Dollar Tree and picked out a variety of glasses.

A trip through the rotary engraver in the laser cutter, a scrub with a brillo pad to remove any roughness on the engraved area, and they came out lookin’ good.

Modular Miniature Building Set

A couple of my friends do miniature gaming, and I found a few websites that specialize in laser-cut miniature buildings and scenery. I saw an idea similar to this, but I made it so that the whole set is modular. Panels can be flipped upside-down or broken, and they all interlock with each other and the floor tiles, so there’s a wide variety of different buildings that could be made quickly.

Brownie-Bite Display

Mom came to me with a small sketch and asked if there was a way to make a display for brownie bite cupcakes for her glass cake display. Yeah, there is.

Mom came to me with a small sketch and asked if there was a way to make a display for brownie bite cupcakes for her glass cake display. Yeah, there is.

Laser-cut ply glued together in layered sections, with a dowel socketed in laser-cut holes. A little family flourish around the lower edge, a coat of water-based poly, and it looks pretty good.

Tree Topper

I made a bunch of small wooden badge ornaments for my co-workers, but then I had an idea for a tree-topper in the same style. Stopped off at Ride-Aid and picked up a tree topper and threw out everything except for the lights. Lased out mirrored acrylic for the front, some plain plastic for the back, and foam-core for the standoffs in between.

Came out pretty well, and got a lot of compliments. Before I make any more, I need to figure out a way to illuminate it better, because buying tree-toppers just for the lights isn’t terribly cost effective. I also need to make sure to use LED only, as incandescent bulbs might get too hot.

Sin Bin Hockey Sticks

A co-worker of mine has a group of gals she goes to hockey games with, called the Sin Bin Gang. We were brainstorming ideas for things they could take with them on the lightthenight.org walk, and we came up with some prop hockey sticks with their nicknames.

Each one is two layers of laser-cut foam-core glued together, and I ran off some decals on the vinyl cutter. All in all, they look pretty sharp. Being made from foam core means that they are super-light, which is handy on a long walk; but it also means they’re pretty fragile, and will easily dent or tear under any kind of abuse.

I also cut some extra vinyl stickers, and recommended that they decorate them as they see fit. I also put their actual names on the back in the same style font as their nickname on the front:

Rose Quartz Sword & Shield

Earlier in the year, Ellen commissioned me to cook up a sword and shield for upcoming Rose City Comic-Con. She commissioned another friend to cook up her dress, but needed a couple props to round out her outfit.

The sword was easy enough, as I just fastened a closet-rod dowel to a pine board, and a couple trips through the bandsaw, table saw (to get the blade bevel), and sander, and the structure was done. Hand guard was shaped from floor mat foam, and the rose pommel was sculpted from clay. This was my first time making something from clay, and it turned out more fragile than I anticipated. I used ‘all-natural’ sculpting/pottery clay, and in the future I will probably try out polymer clay.

The sword was easy enough, as I just fastened a closet-rod dowel to a pine board, and a couple trips through the bandsaw, table saw (to get the blade bevel), and sander, and the structure was done. Hand guard was shaped from floor mat foam, and the rose pommel was sculpted from clay. This was my first time making something from clay, and it turned out more fragile than I anticipated. I used ‘all-natural’ sculpting/pottery clay, and in the future I will probably try out polymer clay.

The shield took a lot longer, because I originally wanted to make it from plastic. If you look online, there are ton of people who have made awesome shields using translucent plastic. However, after scouring the web, I couldn’t find out exactly where they were getting their awesome blanks. In the end, I just gave up and decided to cut the whole thing out of flat MDF wood.

I had plenty of nylon webbing, fasteners, and buckles leftover from when I was making assault rifle slings, so fortunately getting the adjustable straps installed was a breeze using the staple gun.

After the shield was done, I was somewhat dismayed at how heavy it was. Even thin MDF sheets really pack on the weight, and I probably should have used thin ply as the backing material, since it’s not so dense.

I also cut out a Sailor Uranus sword for her alternate costume out of Dollar Tree foam core board. However, the hydrocarbons in the spray paint started eating away at the polystyrene foam core, and the moisture of the paint caused the paper of the surface to gently warp ever so slightly.

Making the whole sword from foam core seemed like a good idea because it was super lightweight, but the structure itself was somewhat flimsy, and in the future I will most likely first cut a thin ‘skeleton’ sheet out of MDF for rigid structure, and then put the foam core on top of that to add dimension without adding weight. And also use much, much thinner layers of spray paint to minimize warping.

Rapid Prototyping

Dollar Tree has big sheets of foam board available for… well… a dollar. It’s cheap and cuts super fast. The edges it leaves are a little fragile because the foam core ‘pulls back’ away from the heat of the laser. that said, it makes an awesome material for rapid prototyping; to realistically show the scale or structure of a project before I cut the actual object from wood or plastic.

Here is the shield and sword Ellen asked me to make, with a couple soda cans for scale. The shield was too big to cut from one piece of material, so I had to cut it from smaller pieces and fit them together in a way so that the seams didn’t overlap.

The sword, on the other hand, was digitally traced from a screen grab, then cut from one piece of foam. But it turned out to be too small, and there was an issue with the ergonomics of the handle. But it only took 40 seconds to cut, and cost me less than a quarter for materials to find all that out, then make the necessary adjustments for the final product.